The functions of the bell spigot SAW Steel Pipes in Sewerage System, Aqueduct Project and Hydroelectric Power Constructions

The functions of the bell spigot SAW Steel Pipes in Sewerage System, Aqueduct Project, and Hydroelectric Power Constructions

The bell spigot is one of the joints of the piping materials. Besides manufacture SAW Steel Pipes, DSAW steel pipes, and SSAW Steel Pipes, we can also process the bell spigot joints for the SSAW Steel Pipes.

What is the bell spigot SAW Steel Pipes?

The bell spigot SAW Steel Pipes are the abbreviation of submerged arc welding steel pipes. There are two classifications of these pipes. These are longitudinal submerged arc welding steel pipes and spiral submerged arc welding steel pipes. LSAW and SSAW are the abbreviations to demonstrate these pipes respectively. SWA is a process that produces a high current density. This high current density helps to concentrate the heat on the welding region.

By focusing the heat on the welding region, saves the amount of heat and prevents its loss. The most common form of the standard used in the process is API 5L.

What's the function of the bell spigot SAW Steel Pipes in Sewerage System?

Which materials to use for sewer pipe installation?

The choice of the materials for the purpose f the installation of the sewer pipe is important. The word “lifespan” is important in the process of installation of the sewer pipes. The manufacturers have to take the material that has a long life. So, lifespan is one of the important factors in determining the characteristics of better bell spigot SAW Steel pipes.

The material that has tremendous use are concrete, steel, plastic, and HDPE type of materials. You will find enough information about these materials. This will help you in the selection of the best material for your product. In this way, you will be able to select a consistent material.

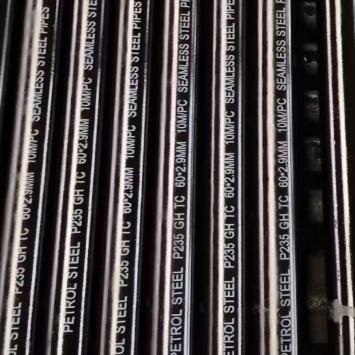

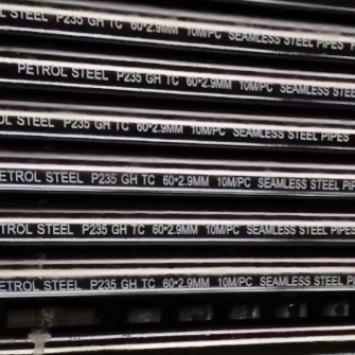

The bell spigot SAW Steel Pipes

Steel is an outstanding material that has the best use in water pipes. However, this material also has tremendous use in sewer pipes. The significant features of this material are durability, strength, and corrosion resistance. The two significant types of this material are cast iron and galvanized iron.

However, this material also bears some drawbacks. In spite of the better strength of the steel, it is also susceptible to the process of rusting. The process of rusting can shorten the lifespan of the material which will cause repairs and replacement issues in the bell spigot SAW Steel Pipes.

Moreover, steel requires the most cost for this purpose. However, steel is a heavy material as compared to plastic. That is why it needs the smaller lengths for this process. If there are more lengths, it will produce more joints that will cause the leakage problems.

What do bell spigot SAW Steel Pipes do?

The fundamental function of the bell spigot SAW Steel Pipes is to maintain the quality of the water in the Sewer system. In addition, they are also important in the assurance of the health of the public. There are many sets of pipes, manholes, and pumping stations that are important in the transfer of water. They pump the water from the industries and business stations to the water treatment plants for the sake of cleaning.

Most of the water in the bell spigot SAW Steel Pipes system comes from the rain and melting snow. The water in these pipes runs with the help of the different mechanisms. In most cases, this water moves to the lakes and streams without any water treatment.

What are some of the characteristics of these piping systems?

Most of the sewer systems have the basis of gravity in order to pump the water. The gravity pumps the water from higher areas to low areas. However, in other cases, there are manholes that pump the water from the low areas to the higher areas. After reaching the higher areas, again gravity comes to the action. The other function of the manholes is to repair any issue in the pipes or amend in the diversion in the path of the sewer system.

The system of conveying in the sewer system is almost similar to the sanitary system. But there is no treatment of the water. However, in the sanitary sewer system, the single pipe carries out both the sanitary waste as well as eh run off together.

What's the function of the bell spigot SAW Steel Pipes in Aqueduct Project?

Aqueducts are structures that have excessive use in the transfer of water for long distances. The structures for transport were open in ancient times. However, nowadays, there are many sources such as tunnels, canals, pipelines, and siphons for this purpose. The tunnels have the use in the transport of trains, water, and other goods. However, those that are larger in size have the use for storage also.

Aqueducts

The use of the aqueducts is from several millennia. The stone collars excavated in the ancient Sumeria. But you can say that the first city to have the aqueducts on a large scale was Rome. The first aqueduct underground was 16km in the length. However, the length of the above-ground aqueduct in 144BC was almost 145km. However, more than 10 aqueducts carried a total of 1.6 m3 s -1 of high-quality water to the fastidious Romans.

These stones had an open structure and had the relatively flat slopes in the structure for the flow. So, the flow was present due to the difference in size and slope. A small gate had the purpose of releasing the water into these structures.

Introduction

The aqueducts in the supply of water mostly have open canals, tunnels, and pipelines. For the efficient supply of water, we may combine these structures. They are also helpful in the water treatment plants and holding a large amount of water in the reservoirs. As there are many types of materials for the bell spigot SAW Steel Pipes. The engineers and contractors have to select these materials for their project after the great research about them.

However, the fundamental and main pipes for the supply of water are of different metals. And most pipes have a diameter between 6 and 16 inches. The next question is about the material type of the pipe and the condition of the system.

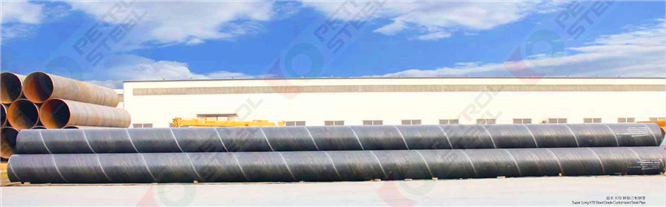

SAW Steel Pipes in Aqueducts Projects

In most cases, the tunnels are in the case of line tunnels for the efficient supply and smooth surface in order to have a better hydraulic flow. But all the tunnels are not lined. Some of the tunnels are unlined and operate for the supply of water and hydraulic systems. Although, there are many materials for the purpose of the lining. But the most important material for this purpose is bell spigot SAW Steel Pipes.

This material is very efficient in its function and has excessive use in the systems where the high pressure of water is present. The thickness of the pipes is according to the faced pressure internally by water. If there is a high pressure, the thickness of the pipe is between 25 to 50 mm. However, in the low pressure of water, the thickness of the pipe maybe 6 to 18 mm.

The function of the bell spigot SAW Steel Pipes in Hydroelectric Power Constructions

There are many composite materials for the equipment of the hydraulic power industry. There are many other applications of this equipment that are important due to their high strength and other distinguishing features. The most important application is in hydroelectric power stations.

Hydroelectric power generation is one of the most significant and clean methods of the production of electricity. The hydroelectric power stations produced 16% of the total electricity in the world in 2012. Therefore, it is the cheapest and renewable source for the production of power. Moreover, there are low costs and expenditure required for the production of electricity.

If the channels are there, the process of excavation is done with the help of the terrain. However, we can also carry this process artificially with the help of concrete structures. Therefore, the best solution to this process is the formation of the concrete tunnel. But the issue is that it requires high costs.

In the final part, the path of the water is to the turbines through the loading chamber. This path requires and makes use of the forced pipe. The bell spigot SAW Steel Pipes are of prime use in these pipes. The reason is that waterfalls from the height of 2000m.

Conclusion

The basic and fundamental factor in the safety and efficiency of the pipe system is the right and true choice of materials. Therefore, we should select the material with the care and precautions. For example, the steel should have the capacity to bear the high temperature and heat during the process in the steel boiler construction. While the material should have effective corrosion resistance in the food industry.

In the same way, the mineral oil processing industry needs materials that have high resistance against heat and press water. Similarly, for the liquefaction and separation of the materials, there should be materials that have high strength. Therefore, there we have a broad range of the materials for their use in the respective type of applications. Therefore, these materials can use a large variety of concrete, steel; bell spigot SAW Steel Pipes and other materials for this purpose.

Final Words

PETROL STEEL CO., LTD has practically all the main technologies for the production of steel pipes. The production of large-diameter pipes from carbon and low-alloy steel at our plants is gaining momentum every year, and the demand for our products is increasing. This is due to a number of advantages:

1. the installation process is simple and does not take much time;

2. the metal is highly durable and resistant to environmental influences;

3. Purchase of the product will be cost-effective.

For each area of application, it is necessary to select the most optimal category of product that will withstand the expected load.

For more technical and commercial details, Please feel free to contact us.

Tel/Fax: +86 10 8599 9168

Whatsapp/Wechat: +86 159 0035 7871

Email: sales@petrolsteel.com, jackywinn@foxmail.com

English

English Chinese

Chinese