seamless pipe oil and gas

Seamless steel tubes are produced from billets, which are heated and perforated to form tubular parts. The word "seamless" means no seams.

seamless pipe oil and gas are used in different applications in the oil and gas industry:

Upstream operation (OCTG pipeline)

Midstream (transfer and distribution of fluids, such as oil, gas, steam, acid, slurry)

Downstream (process pipeline for refining oil and gas in derivatives)

Application of conventional pipeline in public utilities

The most commonly used pipe types in the oil and gas industry are (ASTM pipe specifications):

ASTM A53, A106, A333, and API 5L (carbon steel pipe types for high and low-temperature carbon steel)

ASTM A335 Grade P5 to P91 (for high temperature and high-pressure chromium molybdenum Alloy Steel Pipes, for refineries and power plants)

ASTM A312 series 300 and 400 (grade 304, 316, 321, 347 stainless steel pipe)

ASTM A790 / a928 (dual and super dual-phase tubes with dual ferrite and austenitic structures)

Specifications of various nickel alloy materials (Inconel, Hastelloy, cupronickel, Monel, nickel 200)

Specification of non-ferrous metal pipe (aluminum, copper, brass, cupronickel)

Some codes cover only seamless pipes (e.g. ASTM A106), while others apply to both seamless and welded pipes (e.g. ASTM A53).

Carbon steel pipes (A53, A333, A106 and API 5L) have the largest market share because they can be used in most high and low-temperature applications. The main purpose of stainless steel pipes is for Corrosive Service (higher grade stainless steel pipes will be used as the temperature and pressure rise, or when the delivered fluid becomes more and more corrosive).

The Seamless Steel Pipe shall not be confused with the seamless tube. It is true that there are some important differences between tubes and pipes, which are not only semantic. In general, the term "pipe" applies to any tube used to convey fluid, while the term "tube" applies to tubular parts (various shapes, circles, ellipses, squares) of structural/mechanical applications, instrument systems, and piping. Construction of pressure equipment such as boilers, heat exchangers and superheaters.

oil and gas seamless pipe price

The price of seamless pipes is higher than that of ERW pipes, usually 20% to 30% higher per ton, because their production process is quite complex (clearer than that of ERW and LSAW pipes), and because the number of seamless pipes is very limited (the market is oligopoly).

For specific sizes and specifications (e.g. 20-inch pipe or high wall thickness pipe made of special or special materials, e.g. ASTM A335 P91 pipe), there are few global pipe suppliers, and the price per ton (or per meter) is, therefore, affected.

Therefore, regardless of the actual diameter, wall thickness, and specific grade, it is wrong to use the standard ton price of all "carbon steel" or "stainless steel" pipes to estimate the pipe price: all these factors should be taken into account to prevent cost overruns in the later implementation of the project. In addition, prices fluctuate every day (especially for alloy tubes, which contain molybdenum, nickel, copper, chromium and other chemical elements, which are traded on the London Metal Exchange or ferroalloy market every day).

Seamless pipe size

The ASME B36.10 and B36.19 codes cover the size and weight of seamless tubing for the petrochemical industry (this code also applies to welded tubing):

ASME b36.10 Code covers sizes (sizes and weights) of carbon and low alloy seamless pipe between 1 / 8 and 24 inch

Instead, the ASME b36.19 Code covers the size and weight of stainless steel, duplex, nickel alloy seamless and welded pipe.

The commercial seamless pipe is represented by the nominal pipe diameter (representing the approximate fluid delivery capacity of the pipe) and "schedule", which refers to the thickness of the pipe (the most common are Schedule 40, STD, XS, XXS carbon/alloy pipe, and 10s, the 40s and 80s of stainless steel and nickel alloy pipe).

ASME pipe sizing specifications can be purchased online from the ASME website or the IHS online store.

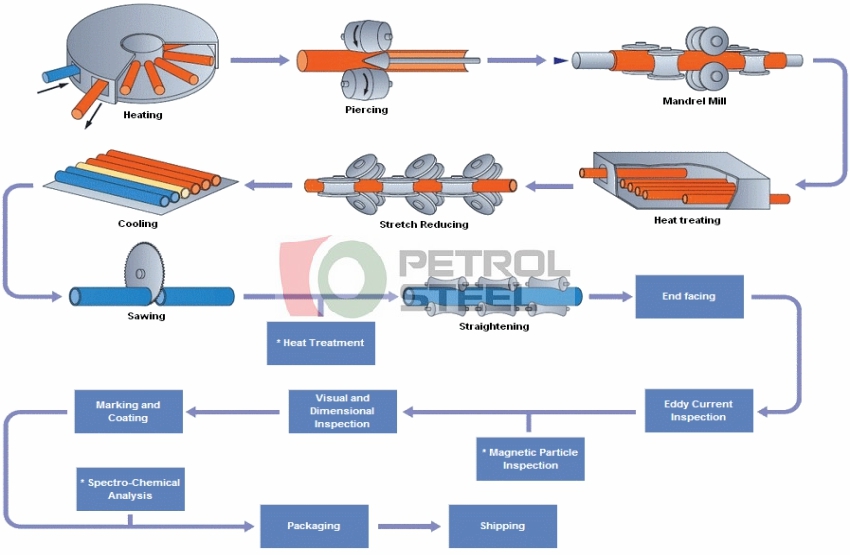

The seamless pipe manufacturing process

One of The Kind, Millions of Choices

Superior Quality,

Prompt Delivery,

Favorable Feedback,

All Available in PESCO

Select PESCO, You Will Be Right!

Your inquiry would be highly appreciated. We would like to cooperate with you for long terms.

Headquarter: A-4F, Vantone Center, A6, Chaowai St., Chaoyang Dist., Beijing, China.

Tel/Fax: +86 10 8599 9168

Whatsapp/Wechat: 0086 159 0035 7871

Email: sales@petrolsteel.com, jackywinn@foxmail.com

English

English Chinese

Chinese