manufacturing process of Welded pipe and tube

manufacturing process of Welded pipe and tube

Since it is possible to make strips and plates, people have been trying to bend materials and connect their edges to make pipes. This led to the development of the oldest welding process, forging welding, which dates back 150 years.

In 1825, James Whitehouse, a British ironmonger, was granted a patent for the manufacture of welded pipes. The process consists of forging a single sheet metal on a mandrel to produce exposed seam tubes, then heating the mating edges of the exposed seams and welding them by mechanically pressing them together in a wire drawing machine.

The technology has been developed to the point where the strip can be formed and welded in one time in a welding furnace. The development of this concept of butt welding culminated in the design of the fretz moon process by American J. moon and his German colleague fretz in 1931.

Today, the welding line using this process is still running in the successful manufacture of pipes with a maximum outer diameter of about 5mm. In addition to the hot press welding technology, which heats the steel strip to the welding temperature in the furnace, e. Thomson of the United States designed several other processes between 1886 and 1890 to enable the metal to be welded. The basis for this is the characteristic found by James P. Joule, by which current passes through a conductor and is heated by its resistance.

In 1898, standard tool company obtained a patent, which covers the application of resistance welding in pipe manufacturing. In the United States and then in Germany, with the establishment of continuous hot strip mills to produce bulk raw materials for mass production, the production of resistance welded pipes and pipes has been greatly improved. During the Second World War, the argon arc welding process was invented again in the United States, which enabled the effective welding of magnesium in aircraft structures.

As a result of this development, various gas shielded welding processes have been developed, which are mainly used in the production of stainless steel pipes. In the past 30 years, there has been a far-reaching development in the field of energy, followed by large-scale building capacity of long-distance pipeline, submerged arc welding technology has become the primary position for welding pipeline with diameter greater than or equal to 10 mm. 500 mm

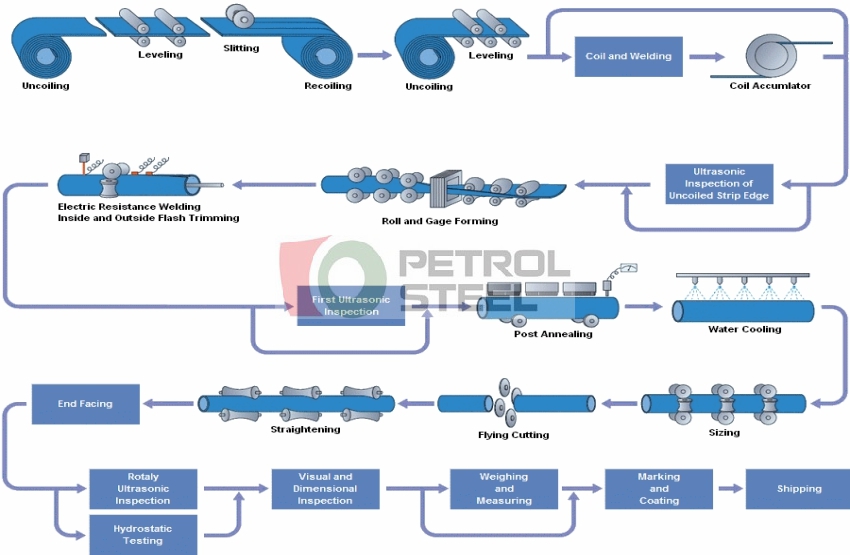

manufacturing process of Welded pipe and tube in the Electric welded pipe factory

The steel strip in the coil has been cut into the required width from the wide strip, and then it is formed into a multi-section length shell through a series of forming rollers. The longitudinal edge is continuously connected by high frequency resistance / induction welding.

Then, the welding seam of the multi-stage shell is processed by the electric head, and it is fixed size and cut into the specified length by the flying shear. Both ends of the cut pipe are straightened and at right angles.

These operations are followed by ultrasonic inspection or hydrostatic testing.

ONE OF THE KIND, MILLIONS OF CHOICES

SUPERIOR QUALITY

PROMPT DELIVERY

FAVORABLE FEEDBACK

ALL AVAILABLE IN PESCO

SELECT PESCO, YOU WILL BE RIGHT

For more info of Flange Dimensions and Specifications, please send us inquiry, you will have quick reply soon.

Headquarter: A-4F, Vantone Center, A6, Chaowai St., Chaoyang Dist., Beijing, China.

Tel/Fax: +86 10 8599 9168

Whatsapp/Wechat: 0086 159 0035 7871

Email: sales@petrolsteel.com, jackywinn@foxmail.com

English

English Chinese

Chinese