Inconel Alloy MA754 UNS N07754 Breakthrough in material properties

Inconel Alloy MA754 UNS N07754 Breakthrough in material propertiesAnalysis of the chemical composition of Inconel MA754 alloy

I. Basic element composition

Matrix elements

Nickel (Ni): 78%, constituting the γ phase matrix of the alloy, providing excellent high temperature stability and ductility.

Chromium (Cr): 20%, enhancing oxidation resistance and corrosion resistance, resisting high temperature oxidation by forming a Cr₂O₃ oxide film.

Trace alloying elements of Inconel MA754 alloy

Aluminum (Al) (0.3%) and titanium (Ti) (0.5%): synergistically enhance the precipitation effect of γ' strengthening phase and optimize high temperature strength

Iron (Fe) (1.0%): assists in stabilizing the austenite matrix structure and reduces process sensitivity 28.

II. Core strengthening components of Inconel MA754 alloy

Yttrium oxide (Y₂O₃): 0.6%, forming a 10-50nm nano-scale dispersed phase through mechanical alloying process , pinning grain boundaries and inhibiting high-temperature creep

Carbon (C): strictly controlled at ≤0.05% to avoid carbide precipitation along grain boundaries causing brittleness.

III. Impurity control standards of Inconel MA754 alloy

The content of trace elements such as manganese (Mn) and silicon (Si) is less than 0.5%, ensuring material purity and processing performance.

IV. Correlation between chemical composition and performance of Inconel MA754 alloy

High-temperature strength maintenance: 78% nickel matrix and Y₂O₃ work together to keep the material at 380MPa tensile strength at 1100°C.

Environmental tolerance: 20% chromium content ensures that the corrosion rate is less than 0.02mm/year in sulfur-containing or neutron irradiation environments.

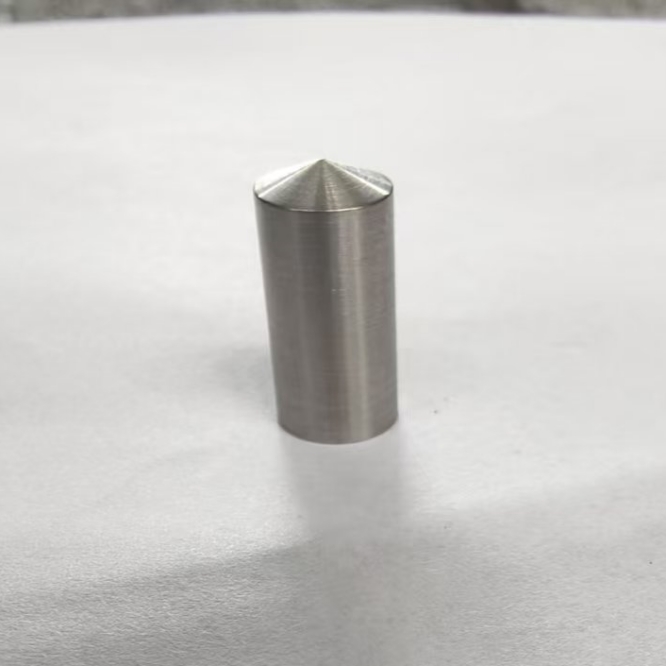

Process adaptability: Accurate composition ratio supports hot isostatic pressing (HIP) molding, and the finished product density can reach 98.5% of the theoretical value.

This chemical system has passed AMS 5898A and ASTM B637 standard certification, becoming the benchmark formula for extreme environment material design.

Analysis of Inconel MA754 alloy heat treatment process of Inconel MA754 alloy

I. Standard heat treatment process

Annealing treatment

Process parameters: keep at 1150-1200℃ for 2-4 hours, then air cool to room temperature.

Mechanism of action: eliminate processing stress, achieve grain homogenization, and restore material ductility.

Solution strengthening treatment of Inconel MA754 alloy

Temperature control: use 1320-1380℃ high temperature solution, and the holding time is calculated according to the section thickness (1.5-2min/mm).

Cooling method: rapid cooling under argon protection, cooling rate ≥55℃/s, inhibiting premature precipitation of γ' phase.

Aging treatment of Inconel MA754 alloy

Phase division:

✓ Phase 1: 840℃×8h insulation to form a uniform Y₂O₃ dispersion distribution.

✓ Second stage: 760℃×16h slow cooling to promote the transformation of metastable phase to stable phase.

II. Key points of process control

Temperature accuracy: All heat treatment stages need to control the furnace temperature fluctuation ≤±5℃ to prevent Y₂O₃ particles from agglomerating.

Atmosphere protection of Inconel MA754 alloy: Argon or vacuum environment (vacuum degree ≤10⁻³Pa) is used throughout the process to avoid surface chromium depletion caused by high-temperature oxidation.

Deformation control under PETROL STEEL CO.,TD: Prestress loading is realized in the heat treatment fixture to control the deformation to ≤0.15mm/m2.

III. Improved performance after treatment

High temperature strength: After complete heat treatment, the tensile strength at 1100℃ can reach 380MPa, which is 40% higher than before treatment.

Creep resistance: The steady-state creep rate under 1200℃/100MPa can be reduced to 1.2×10⁻⁹/s.

This heat treatment specification from www.petrolsteel.com has been incorporated into the AMS 5898A aerospace material standard. In actual application, the holding time parameters can be adjusted according to the workpiece geometry.

Inconel Alloy MA754 UNS N07754, inconel alloy ma754 price, inconel alloy ma754 equivalent, Incoloy Alloy MA956 UNS S67956, inconel alloy MA956 properties, Inconel Alloy MA956, inconel alloy MA956 price, inconel alloy MA956 uses, inconel alloy ma956 vs MA754

Tel/Fax: +86 10 8599 9168

Cel/Whatsapp/Wechat: +86 159 0035 7871

Email: sales@petrolsteel.com, jackywinn@foxmail.com

https://www.petrolsteel.com

https://www.petrolsteel.com/Incoloy-Alloy-MA956-ODS-Steel-p.html

https://www.petrolsteel.com/Material-solution-for-extreme-environments-Inconel-Alloy-MA754-UNS-N07754-n.html

https://www.petrolsteel.com/Inconel-Alloy-MA754-UNS-N07754-Breakthrough-in-material-properties-n.html

English

English Chinese

Chinese