Description

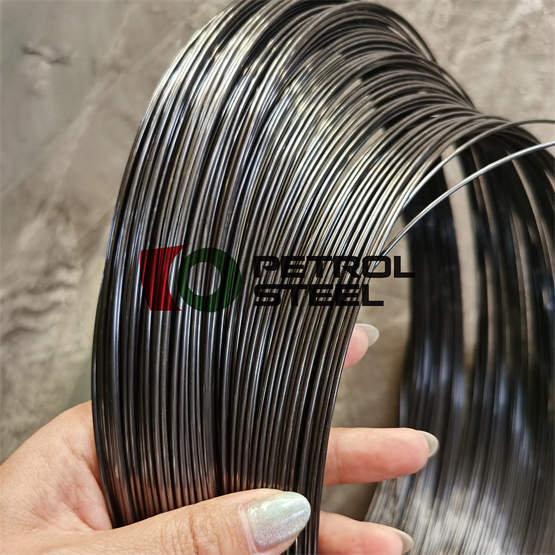

Material: Made of high-quality low carbon steel wire rod

Process: hot-dip galvanized iron wire, electroplated iron wire.

Specifications: Hot-dip plating: 8# - 36# (3.8mm, 0.19mm).

Electroplating: 8# - 38# (3.8mm-0.15mm).

Our productions include but not limited the following items:

galvanized wire spools, galvanized wire rods, galvanized spooled wire, galvanized Annealed Wire, Welded galvanized Wire Mesh, galvanized Razor Barbed Wire, galvanized Gabion Mesh, Galvanized Steel Hobby Wire, Galvanized Steel Wire Ropes, Welded Wire Fence Rolls, Galvanized Wire Mesh Fence, Agricultural Wire Fencing Stock, etc.

Uses: Mainly used in communication equipment, medical equipment, woven nets, brushes, wire ropes, filters, high-pressure pipes, construction, handicrafts, and other industries.

PESCO Hot Dipped Galvanized Wires can be divided according to their use:

22# (0.71mm) iron wire used for construction bundling, low price, good flexibility, and not easy to break. It is one of the most ideal tying wires in the construction industry, mainly using low-zinc cold-plated iron wire. Mainly use low zinc cold dipped iron wire.

The handicraft iron wire is specially processed with a single wire, without breakage, the amount of zinc applied is uniform and bright, and the price is generally slightly more expensive.

Galvanized wire also includes spreading wire: each coil weighs about 100kg-1000kg and is mainly used in industry, agriculture, and animal husbandry.

Tensile strength and calculation method of galvanized wire

Wire cross-sectional area=diameter square*0.7854mm2

Wire breaking tensile force Newton (N) / cross-sectional area mm2 = strength MPa

Production process: It is made of high-quality low-carbon steel wire rod, which is made of high-quality low-carbon steel through drawing, pickling, rust removal, high-temperature annealing, hot-dip galvanizing, cooling, and other processes. Characteristics of PESCO Hot Dipped Galvanized Wires: The galvanized wire has good toughness and elasticity, and the maximum amount of zinc can reach 300 grams/square meter. It has the characteristics of a thick galvanized layer and strong corrosion resistance. PESCO Hot Dipped Galvanized Wires application: The products are widely used in various fields such as construction, handicrafts, weaving wire mesh, highway guardrails, product packaging, and daily civil use. 1: Galvanized wire is divided into hot-dip galvanized wire and cold galvanized wire (electro-galvanized wire). The difference is: Hot-dip galvanized is immersed in a heated and melted zinc solution. The production speed is fast, and the coating is thick but uneven. The minimum allowed thickness is 45 microns and the maximum can be over 300 microns. The color is darker, consumes a lot of zinc metal, forms an infiltration layer with the base metal, and has good corrosion resistance, and hot-dip galvanizing can be maintained for decades in an outdoor environment. 2: Cold galvanizing (electro-galvanizing) is to gradually coat zinc on the metal surface through the unidirectional current in the electroplating tank. The production speed is slow, the coating is uniform, and the thickness is thin, usually only 3-15 microns, with a bright appearance and corrosion resistance. Poor performance usually rusts in a few months. Compared with electro-galvanizing, hot-dip galvanizing is less expensive to produce and has less impact on the environment than electroplating. Specifications Hot-dip galvanizing: 8#—36# (4.0mm, 0.19mm) Electroplating: 8#—38# (4.0mm-0.15mm) Packing form: shaft wire, disc (inner plastic outer braid, inner plastic outer hemp). Application range of galvanized wire: Due to the thicker coating obtained, hot-dip galvanized wire has better protective performance than electro-galvanized wire, so it is an important protective coating for steel products used in harsh working environments. Hot-dip galvanized wire is widely used in chemical equipment, petroleum processing, marine exploration, metal structure, power transmission, shipbuilding, and other industries. , highway guardrails, etc., have been widely used in recent years.

Characteristics and technical requirements of PESCO Hot Dipped Galvanized Wires

Production process: It is made of high-quality low-carbon steel wire rods, which are made of high-quality low-carbon steel through drawing, pickling, rust removal, high-temperature annealing, hot-dip galvanizing, and cooling.

Galvanized wire characteristics: PESCO Hot Dipped Galvanized Wires have good toughness and elasticity, and the maximum amount of zinc can reach 300 grams/square meter. It has the characteristics of a thick galvanized layer and strong corrosion resistance.

Galvanized wire application: PESCO Hot Dipped Galvanized Wires are widely used in various fields such as construction, handicrafts, weaving wire mesh, highway guardrails, product packaging, and daily civil use.

Galvanized wire is divided into hot-dip galvanized wire and cold galvanized wire (electro-galvanized wire), the difference is:

Hot-dip galvanizing is dipping in a heated and molten zinc solution. The production speed is fast, and the coating is thick but uneven. The minimum thickness allowed by the market is 45 microns, and the maximum thickness is more than 300 microns. The color is darker, consumes a lot of zinc metal, forms an infiltration layer with the base metal, and has good corrosion resistance, and hot-dip galvanizing can be maintained for decades in an outdoor environment.

Cold galvanizing (electro-galvanizing) is gradually coating zinc on the metal surface through the unidirectional current in the electroplating tank, the production speed is slow, the coating is uniform, the thickness is thin, usually only 3-15 microns, the appearance is bright, and the corrosion resistance is poor. It usually rusts in a few months.

Compared with hot-dip galvanizing, the production cost of electro-galvanizing is lower.

The difference between cold galvanizing and hot-dip galvanizing:

The difference between cold galvanizing and hot-dip galvanizing is that the amount of zinc applied is different, and they can be identified by color. The color of cold galvanizing is bright, silver-white, and yellow. Hot-dip galvanized shiny white.

Scope of application of hot-dip galvanizing:

Due to the thicker coating obtained, PESCO Hot Dipped Galvanized Wires have better protective properties than electro-galvanizing, so it is an important protective coating for steel parts used in harsh working environments. Hot-dip galvanized products are widely used in chemical equipment, petroleum processing, marine exploration, metal structure, power transmission, shipbuilding and other industries. , highway guardrails, etc., have been widely used in recent years.

Production process of PESCO Hot Dipped Galvanized Wires: It is made of high-quality low-carbon steel wire rod, which is made of high-quality low-carbon steel, after drawing, pickling, rust removal, high temperature annealing,

Hot-dip galvanizing. Cooling and other technological processes are processed.

Characteristics of galvanized wire: Galvanized iron wire has good toughness and elasticity, and the maximum amount of zinc can reach 300 grams/square meter. With a thick galvanized layer, anti-

Corrosive and other characteristics.

Galvanized wire application: The products are widely used in construction, handicrafts, weaving wire mesh, highway guardrails, product packaging and daily civil use, etc.

an area.

Galvanized wire is divided into PESCO Hot Dipped Galvanized Wires and PESCO cold-galvanized wires (electro-galvanized wire), the difference is:

Hot-dip galvanizing is immersion plating in heated and molten zinc solution. The production speed is fast, and the coating is thick but uneven. The minimum thickness allowed by the market is 45 microns.

The height can reach more than 300 microns. The color is darker, consumes a lot of zinc metal, forms an infiltration layer with the base metal, has good corrosion resistance, and is hot-dip galvanized in outdoor environment

can last for decades.

Cold galvanizing (electro-galvanizing) is to gradually coat zinc on the metal surface through the unidirectional current in the electroplating tank, the production speed is slow, the coating is uniform and thick.

The thickness is thin, usually only 3-15 microns, the appearance is bright, the corrosion resistance is poor, and it will rust in a few months.

Compared with hot-dip galvanizing, the production cost of electro-galvanizing is lower.

The difference between cold galvanizing and hot galvanizing:

The difference between cold galvanizing and hot-dip galvanizing is that the amount of zinc applied is different, and they can be identified by color. The color of cold galvanizing is bright, silver-white and yellow. hot

Galvanized shiny white.

Hot dip galvanizing application range:

Due to the thicker coating obtained, hot-dip galvanizing has better protective properties than electro-galvanizing, so it is an important choice for steel parts used in harsh working environments.

To protect the coating. Hot-dip galvanized products are widely used in chemical equipment, petroleum processing, marine exploration, metal structure, power transmission, shipbuilding and other industries.

It can be used in agricultural fields such as pesticide sprinkler irrigation, greenhouse and construction industries such as water and gas transmission, wire casings, scaffolding, bridges, highway guardrails, etc.

In recent years, it has been widely used.

How to distinguish between cold galvanized welded wire mesh and modified wire welded wire mesh? Maybe you will feel some doubts, I am here to tell you

Analyze the differences between cold galvanized welded wire mesh and wire-drawn welded wire mesh.

Manufacturing process: Cold galvanized welded wire mesh is a process in which low carbon steel wire is first welded and then galvanized, that is, first welding and then plating. change

The wire drawing welded wire mesh is also a kind of galvanized wire, which is then directly welded, that is, first plated and then welded. Cold galvanized welded wire mesh is first welded

After galvanizing, the solder joints cannot be seen. On the contrary, the welded wire mesh has solder joints.

Appearance: visually modified wire is brighter than cold galvanized wire.

Production cost: The cost of cold galvanized welded wire mesh is higher than that of wire-drawn welded wire mesh.

Anti-corrosion ability: cold galvanized welded wire mesh has stronger anti-corrosion ability than wire-drawn welded wire mesh.

Flexibility of welded wire mesh: The wire-drawn welded wire mesh is tougher (harder) than the cold galvanized welded wire mesh.

The amount of zinc on the wire: the zinc content of the cold galvanized welded wire mesh is higher than that of the wire-drawn welded wire mesh.

Production speed of the steel wires: The wire drawing welded wire mesh has less process than the cold galvanized welded wire mesh, and the production speed is fast.

Galvanized wires can be divided into: hot-dip galvanized iron wire, electroplated iron wire according to the production process

Hot-dip plating: 8#—36# (3.8mm, 0.19mm)

Electroplating: 8#——38# (3.8mm-0.15mm)

Production process: It is refined through 5 working processes such as drawing and forming of high-quality low-carbon steel wire rods, pickling and rust removal, high temperature annealing, hot-dip galvanizing, and cooling.

Galvanized wire features: good toughness and elasticity, strong corrosion resistance.

Uses: Mainly used in communication equipment, medical equipment and woven nets, brushes, steel cables, filters, high-pressure pipes, construction, handicrafts and other industries

Electro-galvanized wire: It is a metal composite material made of low-carbon steel as the core wire and processed by wire drawing and electro-galvanizing process.

Nowadays, the application of steel bars in the construction industry is very large. When it comes to the use of steel bars, we have to mention the binding wires used for binding steel bars. This binding wire is made of PESCO Hot Dipped Galvanized Wires.

Wire and burnt iron wire. Galvanized steel wire is generally used. However, when the steel wire is in short supply, thin iron wire can also be used, which becomes soft after being burned.

So it is also called burning iron wire.

The commonly used specifications of tie wire are 18 to 22. When the diameter of the binding steel bar is less than 12 mm, it is suitable to use No. 22 wire; when it is 12 to 25 mm, it is suitable to use No. 20.

When the wire is more than 25 mm, the 18-gauge wire should be used. The length of the tie wire should not be too long or too short. If it is long, it will cause waste, and if it is short, it will be inconvenient to handle.

do. The length of the tie wire is generally in order to enable the wire tie hook to be twisted for 2-3 turns, and then leave about 10 mm. Since the ties are often supplied in discs, it is customary to cut them at a fraction of the circumference of each disc.

Tie wires including PESCO Hot Dipped Galvanized Wires are a metal wire drawn from mild steel. Binding wire is divided into: galvanized binding wire, pvc binding wire, plastic-coated binding wire, stainless steel binding wire, iron wire binding

silk etc.

The use of tying wire is different, and the composition is different. It contains: iron, cobalt, nickel, copper, carbon, zinc, and other elements. blazing gold

The metal billet is rolled into a 5mm thick steel bar, and then put into the wire drawing device and drawn into wires of different diameters, and the diameter of the wire drawing disc is gradually reduced for cooling,

Annealing, coating and other processing processes are made into various specifications of iron wire.

The specifications of binding wire for binding are as follows according to the industry standard: 25# iron wire with a diameter of 0.50mm, 24# iron wire with a diameter of 0.55mm, and a wire with a diameter of 0.60mm.

23# iron wire and 0.70mm diameter 22# iron wire, etc.

In order to avoid frequent maintenance, wire binding has been increasingly used in daily life and high-end leisure places. The low carbon steel coil wire produced by our galvanized wire factory relies on Excellent corrosion resistance and flawless surface quality. It has been widely used in many leisure and entertainment places, families, enterprises and so on.

English

English Chinese

Chinese