Blind Flanges Full-Dimensional Solution: From Technical Parameters To Industry Practice

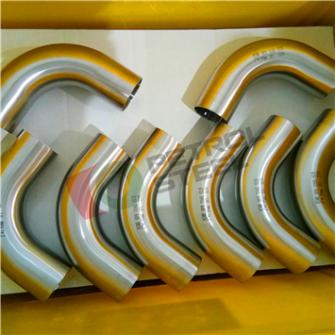

As the "safety gate" of the pipeline system, PETROL STEEL Blind Flanges adopts a modular design concept to achieve full-scenario coverage from conventional working conditions to extreme environments. According to Market Research Future data, the global flange market size will reach US$7.6 billion in 2024, of which Blind Flanges account for more than 35% in maintenance and isolation scenarios.PETROL STEEL CO., LTD produces various kinds of flanges, including Weld neck flanges, Blind flanges, Slip-on flanges, Socket Weld flanges, Lap Joint flanges, Threaded flanges, Weldlet, socklet, elbolet, sweepolet, threadlet, Latrolet, Brazolet, Coupolet, Nipolet, Sweepolet, Weldoflange, Flexolet, etc.

The materials we can produce are carbon steel, stainless steel, alloy steel, Carbon Steel, Stainless Steel, Duplex, Alloy Steel, Nickel Alloys, Super Alloys, Titanium, Cladding etc.

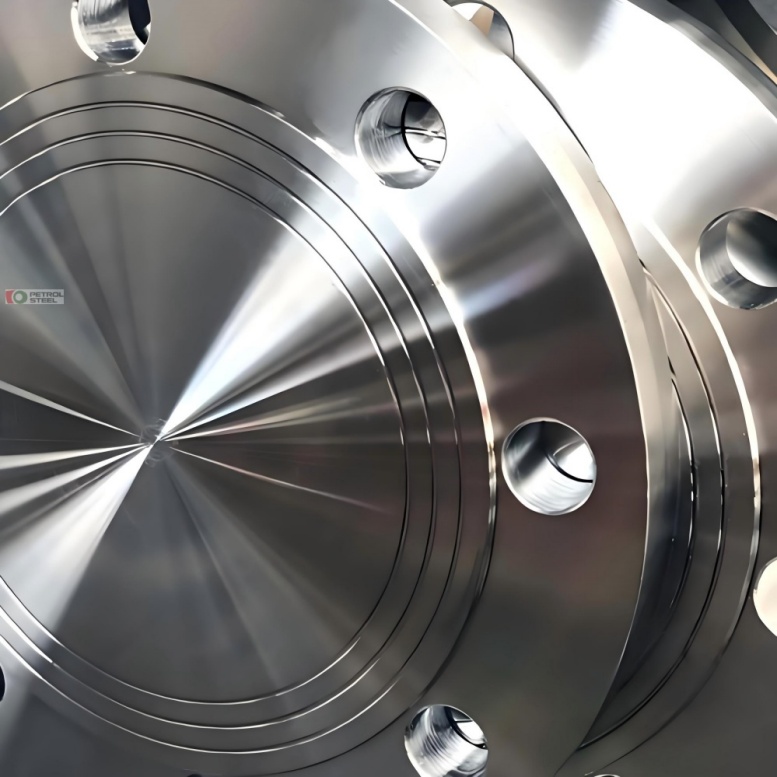

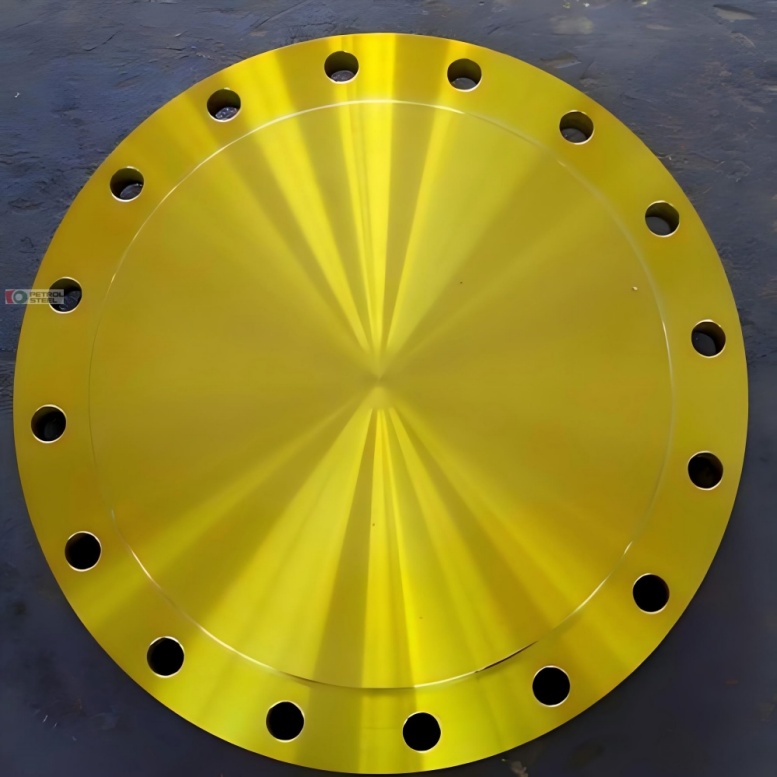

PETROL STEEL Blind Flanges is a flange without a hole in the middle, which is connected to the matching flange by bolts and is used to permanently or temporarily block the end of the pipeline, equipment interface or isolation pipe section. Its core value includes but is not limited to: cutting off the flow of media during maintenance, pressure testing or process changes, and safely isolating the fluid medium; cooperating with the 8-shaped blind plate to realize the on-off switching of the pipeline, with flexible system segmentation function; timely cooperating to block redundant pipeline interfaces such as reserved ports and abandoned branches;

The difference between PETROL STEEL Blind Flanges and ordinary flanges: ordinary flanges are used to connect pipelines and have through holes; PETROL STEEL Blind Flanges are solid plate flanges, which are only used for blocking and can be disassembled and reused.

The installation operation specifications, details and requirements of PETROL STEEL Blind Flanges in industry projects must also meet the standards. The preparation before installation includes many steps: selection and matching, pressure level, sealing surface type (convex surface/RF, ring groove surface/RJ, etc.) must be consistent with the pipeline system flange; anti-sulfur materials (such as NACE MR0175 standard) are selected for acidic environments; overall inspection of the construction site; cleaning of oil stains, burrs, etc. on the flange sealing surface, and the flange gasket must be complete and free of indentations.

The technical parameter system of PETROL STEEL Blind Flanges is relatively comprehensive and complete. PETROL STEEL Blind Flanges have a variety of material types. Their diverse materials and typical hardness special treatments can be applied to various relevant standards, such as ASTM A105A SME B16.5, HB≤187 normalizing treatment, F316L NACE MR0103 HRB≤90 solution annealing, Duplex 2205 ASTM A182 HRC28-32 cold working strengthening and other standards; PETROL STEEL Blind Flanges have excellent performance advantages and bursting pressure, and its pressure is 4.2 times the rated pressure (third-party SGS test report); its sealing level is ISO 5208 Type A zero leakage; it has excellent fatigue resistance, and 20,000 pressure cycle tests have no failure; PETROL STEEL Blind Flanges' connection technology is bolt connection, and it provides supporting preload calculation software (including ASME PCC-1 algorithm), and its welding type is groove design, which fully complies with ASME B31.3 specification; it has the characteristics of quick locking: patented clamp design (installation time is shortened by more than 70%).

The engineering application guide and installation specifications of PETROL STEEL Blind Flanges are as follows: Torque control requires a step-by-step tightening method (50%-80%-100% in three stages); the laser calibration deviation in the centering requirement is ≤0.1mm/m; for pressure testing, our company recommends the use of helium mass spectrometry leak detection (sensitivity up to 1×10⁻⁹ mbar·L/s); the working condition adaptation table also has clear regulations and requirements for environmental types, recommended materials, and protection solutions. For example, in the use environment of offshore platforms, the requirements for Super Duplex nickel-based alloy spraying requirements and the certified low temperature and -196℃ impact test requirements and specifications for Inconel 625NORSOK M-650 in sour oil and gas and LNG9%Ni steel.

There are many project cases of PETROL STEEL Blind Flanges, among which the more typical ones are: Class 900 RTJ Blind Flanges used in the Central Asian Natural Gas Pipeline Project achieved 10 years of maintenance-free operation at -45℃; 304L Blind Flanges used in the Zhejiang Petrochemical Base Project successfully resisted polysulfuric acid stress corrosion (according to NACE TM0177 standard). In the South China Sea floating production unit, integrated intelligent Blind Flanges (with pressure sensing module) are used to achieve remote monitoring, etc.

There are many standard certification systems for Blind Flanges, including international standards API 6A (wellhead equipment level) and EN 1092-1, international industry standards Shell DEP 34.19.10.12 and Equinor TR2317, and Chinese industry standards NB/T 47023-2012 Special Standard for Pressure Equipment.

The dimensions and the tolerances under the standards that we can produce:

ANSI B. 16.5 – Steel Pipe Flanges and Flanged Fittings (½ inch to 24 inch nominal diameter)

MSS SP.6 – Flange Facings

MSS SP.25 – Marking of flanges

MSS SP.39 – Bolts and Nuts for Flanges

MSS SP.44 – Large Diameter Pipeline Flanges. (Over 24 inch dia)

API-605 – Large Diameter Flanges for Petroleum Usage. (Over 24 inch dia)

Market prospect analysis of Blind Flanges. According to Global Market Insights' forecast, the market for Blind Flanges will maintain a compound annual growth rate of 4.8% from 2025 to 2030. The main driving forces include: the eastward shift of global refining and chemical capacity (the Asia-Pacific region will account for 42%), the demand for hydrogen pipeline construction under the background of carbon neutrality, and the wave of renovation of old pipelines (the United States needs to replace about 320,000 kilometers of dangerous and old pipelines).

Contact Us Today, sales@petrolsteel.com, whatsapp: +86 159 0035 7871 for the best price and instant delivery.

For more tehchnical information and available stocks of superior flanges and fitings, please click the links:

https://www.petrolsteel.com/PETROL-STEEL-Weldolet-flanges-the-branching-platform-reliable-branching-expert-for-industrial-piping-systems-n.html

https://www.petrolsteel.com/High-Pressure-Flange-p.html

https://www.petrolsteel.com/Forged-Pipe-Fitting-p.html

English

English Chinese

Chinese