Large Diameter Hot-Expanded Seamless Steel Pipes - The Preferred Material For Long-Distance Pipeline Infrastructure

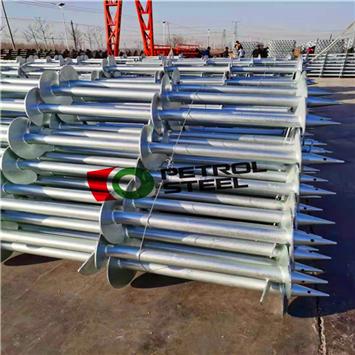

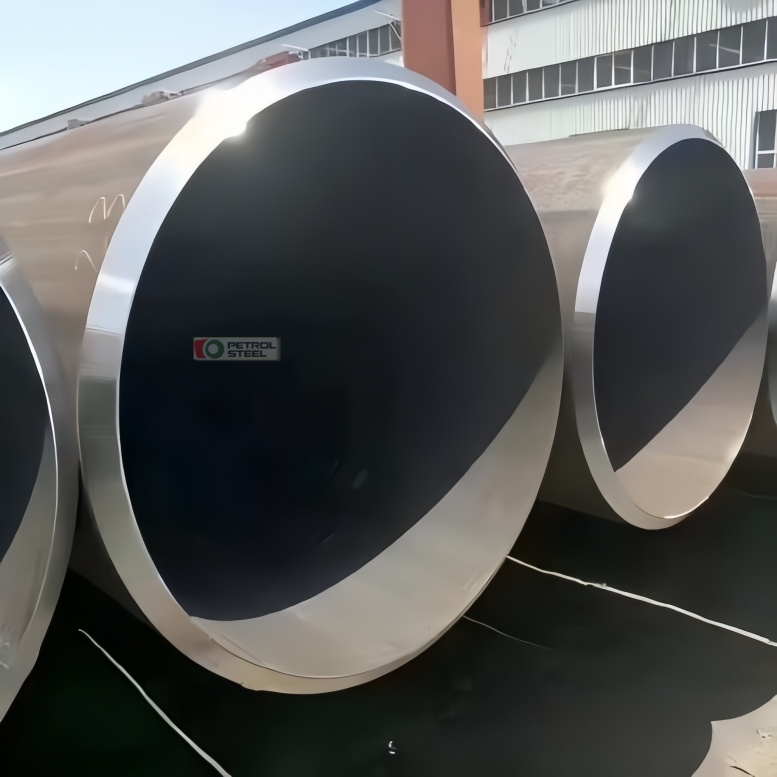

Large diameter hot-expanded Seamless Steel Pipes, as the core components of modern industrial pipeline systems, are widely used in energy, chemical industry, infrastructure, and other fields with their excellent pressure bearing capacity, corrosion resistance, and adaptability to complex working conditions.PETROL STEEL CO., LTD. is a professional supplier of large-diameter hot-expanded Seamless Steel Pipes. Our company expands the diameter of small-diameter Seamless Steel Pipes to Φ508mm-Φ1420mm through the hot expansion process, so that large-diameter hot-expanded Seamless Steel Pipes have both the strength of seamless pipes and the large-diameter advantages of welded pipes.

The core performance indicators of large diameter hot-expanded Seamless Steel Pipes include: Mechanical properties: tensile strength ≥485MPa, yield strength ≥245MPa (taking Q345 as an example), corrosion resistance: can be improved by internal and external coatings (3PE, FBE) or galvanizing, dimensional accuracy: outer diameter tolerance ±1%, wall thickness tolerance ±10%.

The connection and installation methods of large-diameter hot-expanded seamless steel pipes include: connection method: welding (double-sided submerged arc welding), flange connection or mechanical coupling, installation angle: support horizontal, vertical and inclined installation (need to cooperate with the support and hanger system), pressure level: PN10-PN160 (up to 16MPa).

The process and quality control of large-diameter hot-expanded seamless steel pipes include: thermal expansion process verification, temperature control: expansion temperature ≤900℃ to avoid grain coarsening; cooling method: forced water cooling process to increase yield strength by 15%.

The list of mandatory inspection items for large diameter hot-expanded seamless steel pipes before leaving the factory includes: non-destructive testing: 100% ultrasonic flaw detection (GB/T 5777) 68; mechanical properties: transverse tensile test (yield strength ≥355MPa) 10; corrosion test: H₂S environment requires NACE TM0177 standard sulfur resistance test.

The use environment of large diameter hot-expanded seamless steel pipes includes: Applicable media: crude oil, natural gas, steam, acid and alkali solution (material matching required), working temperature: -40℃~450℃ (impact test required for low temperature), environmental requirements: extreme environments such as land, sea, polar regions (special anti-corrosion design required).

large diameter hot-expanded seamless steel pipes have many advantages, including but not limited to: Economical: 20%-30% lower cost than traditional cast pipes, long service life: design life ≥30 years (in line with API 5L/GB/T 5310 standards), fast delivery: hot expansion process shortens production cycle by more than 50%.

The application scenarios and cases of large-diameter hot-expanded seamless steel pipes.

Applications in energy transmission systems include: petroleum and natural gas industry: China-Russia East Line Natural Gas Project (Φ1420mm X80 steel grade), power industry: supercritical boiler high-temperature steam pipeline (P91 material), municipal industry: urban heating pipeline network (prefabricated insulation pipe structure),

As steam pipelines, in the main application of supercritical generator sets, use ASTM A335 P91 material hot-expanded pipes (such as specifications 530×20mm), temperature resistance 650℃ applied to the boiler superheater system 35, process requirements: forced normalizing + tempering treatment, grain size ≥8 grade.

Applications in infrastructure and chemical engineering include: as a large bridge pier, 480×20mm 16Mn steel, compressive strength ≥490MPa, extending the life of the bridge by 30%; as a chemical reactor support, 426×30mm Alloy Steel Pipe, resistant to hydrogen sulfide corrosion (sulfur content ≤0.005%); as a city heating network pipeline, 630×10mm P265GH, EN 10216-2 standard, -50℃ low temperature toughness meets the standard, a refining base uses 426×30mm thermal expansion pipe to support the reactor, reducing the vibration stress of the equipment by 40%.

Applications in ship and marine engineering projects include: as a ship hydraulic pipeline system, a 480×20mm 16Mn seamless pipe is used for steering gear hydraulic pipeline, with a pressure of 35MPa, and the internal defects are detected by magnetic flaw detection.

As a structural pipe, in the application of offshore platform projects, a 720×14mm thermal expansion pipe is used as a conductor frame support, with 3PE anti-corrosion coating, and the anti-seawater corrosion life exceeds 25 years. LNG fuel powered ship pipeline, double wall hot expansion pipe (material 022Cr17Ni12Mo2) transports low-temperature liquefied gas, no brittle cracking at -196℃.

Application in special industrial scenarios, as a nuclear power primary loop pipeline pipe ASME SA335 standard 820×14mm hot expansion pipe, 100% ultrasonic flaw detection to ensure zero defects; high-pressure boiler parts T/CISA 002-2017 standard 630×9mm products, used for power station boiler economizer.

PETROL STEEL CO., LTD produces the following materials of the large-diameter hot-expanded seamless steel pipes.

International: API 5L, ASTM A106/A335

Domestic: GB/T 5310, SY/T 5037

Industry certification: ISO 9001, CE/PED

ASTM A106 Gr. A,

ASTM A106 Gr. B,

ASTM A106 Gr. C,

ASTM A333 Gr.3,

ASTM A333 Gr.6,

ASTM A335 P5,

ASTM A335 P91,

EN 10216-1/2 P235GH,

EN 10216-1/2 P265GH.

Contact Us Today, sales@petrolsteel.com, whatsapp: +86 159 0035 7871 for the best price and instant delivery.

For more tehchnical information and available stocks of superior Large Diameter Hot-Expanded Seamless Steel Pipes, please click the links:

https://www.petrolsteel.com/Large-Diameter-Steel-Pipe-p.html

https://www.petrolsteel.com/Seamless-Steel-Pipe-p.html

https://www.petrolsteel.com/SCM440-Steel-42CrMo4-Alloy-p.html

https://www.petrolsteel.com/SSAW-Steel-Pipe-Bell-Spigot-p.html

https://www.petrolsteel.com/LSAW-Steel-Pipe-p.html

English

English Chinese

Chinese