Petrol Steel Weldolet Flanges - The Branching Platform Reliable Branching Expert For Industrial Piping Systems

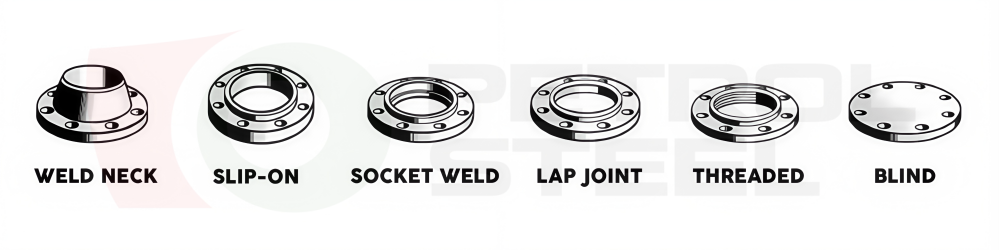

PETROL STEEL CO., LTD., through forging and self-reinforcement design, provides zero-leakage pipeline branching solutions for high-pressure/high-temperature working conditions.We can manufacture the kinds of types of the flanges: Weldlet, socklet, socklet, elbolet, Weld neck flange, Slip-on flange, Socket Weld flange, Lap Joint flange, Threaded flanges, Blind flange, sweepolet, threadlet, Latrolet, Brazolet, Coupolet, Nipolet, Sweepolet, Weldoflange, Flexolet, etc.

The materials we can produce are carbon steel, stainless steel, alloy steel, Carbon Steel, Stainless Steel, Duplex, Alloy Steel, Nickel Alloys, Super Alloys, Titanium, Cladding etc.

PETROL STEEL Weldolet's product technical specifications and product structural characteristics include: product connection method: ASME B16.9 standard butt welding joint, full penetration weld design; product installation angle: 90° standard type (optional 45° bevel version); product pressure level: Class 300-2500 (supports customized 9000LB ultra-high pressure version).

PETROL STEEL Weldolet's material and media adaptability are: The product material has flexible selection: according to different working conditions and customer needs, you can choose: carbon steel (A105), stainless steel (316L), nickel-based alloy (Inconel 625) and other materials. The product has wide compatibility with the media used: it can be used for complex media such as sour oil and gas (NACE MR0103 certification) and high-purity chemicals (EP polishing treatment).

The advantages of PETROL STEEL Weldolet in engineering use include: Improved product service life: Compared with castings, PETROL STEEL Weldolet forging can increase the fatigue life of the product by more than 5 times. The cost advantage of our company's Weldolet production and installation: it can reduce 50% of the welding work time and reduce the overall installation cost by more than 30%.

PETROL STEEL Weldolet is widely used in typical projects and projects. Examples include: Widely used in refining and chemical engineering projects: PetroChina's 10 million ton refinery reforming unit pipeline (material A182 F316H, design pressure 15MPa). Used in key projects on offshore platforms: South China Sea gas field undERWater pipeline system (passed API 6A SSV valve group test).

PETROL STEEL Weldolet's quality assurance includes: production standards comply with ISO 9001:2015 system certification. Inspection methods include 100% UT ultrasonic flaw detection (ASTM E317 standard). Before shipment, third-party SGS, BV, TUV and other installation materials can be re-inspected according to customer requirements. Delivery form: vacuum anti-rust packaging, with EN 10204 3.1 material certificate

Our company can provide value-added services, including stress analysis reports (based on CAESAR II software) and remote or on-site welding technical guidance (AWS certified engineers are stationed in the factory).

Contact Us Today, sales@petrolsteel.com, whatsapp: +86 159 0035 7871 for the best price and instant delivery.

For more tehchnical information and available stocks of superior flanges and fitings, please click the links:

https://www.petrolsteel.com/High-Pressure-Flange-p.html

https://www.petrolsteel.com/Forged-Pipe-Fitting-p.html

English

English Chinese

Chinese